August 15, 2022 —— Mech-Mind officially introduces the 4th generation Mech-Eye PRO high-accuracy industrial 3D camera. Compared to the previous generation, the new Mech-Eye PRO provides 100% improved ambient light resistance (applicable to the monochrome version), 75% lower temperature drift, 40% faster scanning speed, and a 40% more compact design. Extending the remarkable performance of the previous generation, the fully-upgraded Mech-Eye PRO is designed for typical medium-range robotic applications.

Combining high accuracy with fast scanning speed, extended FOV, and improved stability, the 4th generation Mech-Eye PRO delivers new levels of performance, easily handling demanding applications like random bin picking, high-precision assembly, academic research, etc.

Mech-Eye PRO has been widely used in multiple applications across diverse industries, including automotive, manufacturing, construction machinery, home appliances, etc.

┃ Outstanding Performance

01

High-Quality 3D Images for A Broad Range of Objects

The new Mech-Eye PRO can generate accurate, detailed, and complete point clouds of a broad range of objects, including metals, plastics, wood, etc.

With 100% improved ambient light resistance*, the new Mech-Eye PRO can provide high-quality 3D images under demanding light conditions (> 20,000 lx).

The enhanced ambient light resistance performance of Mech-Eye PRO does not only guarantee a more consistent performance under challenging light conditions but also helps save costs due to the reduced need for shading facilities.

(*applicable to monochrome version, compared to the previous generation)

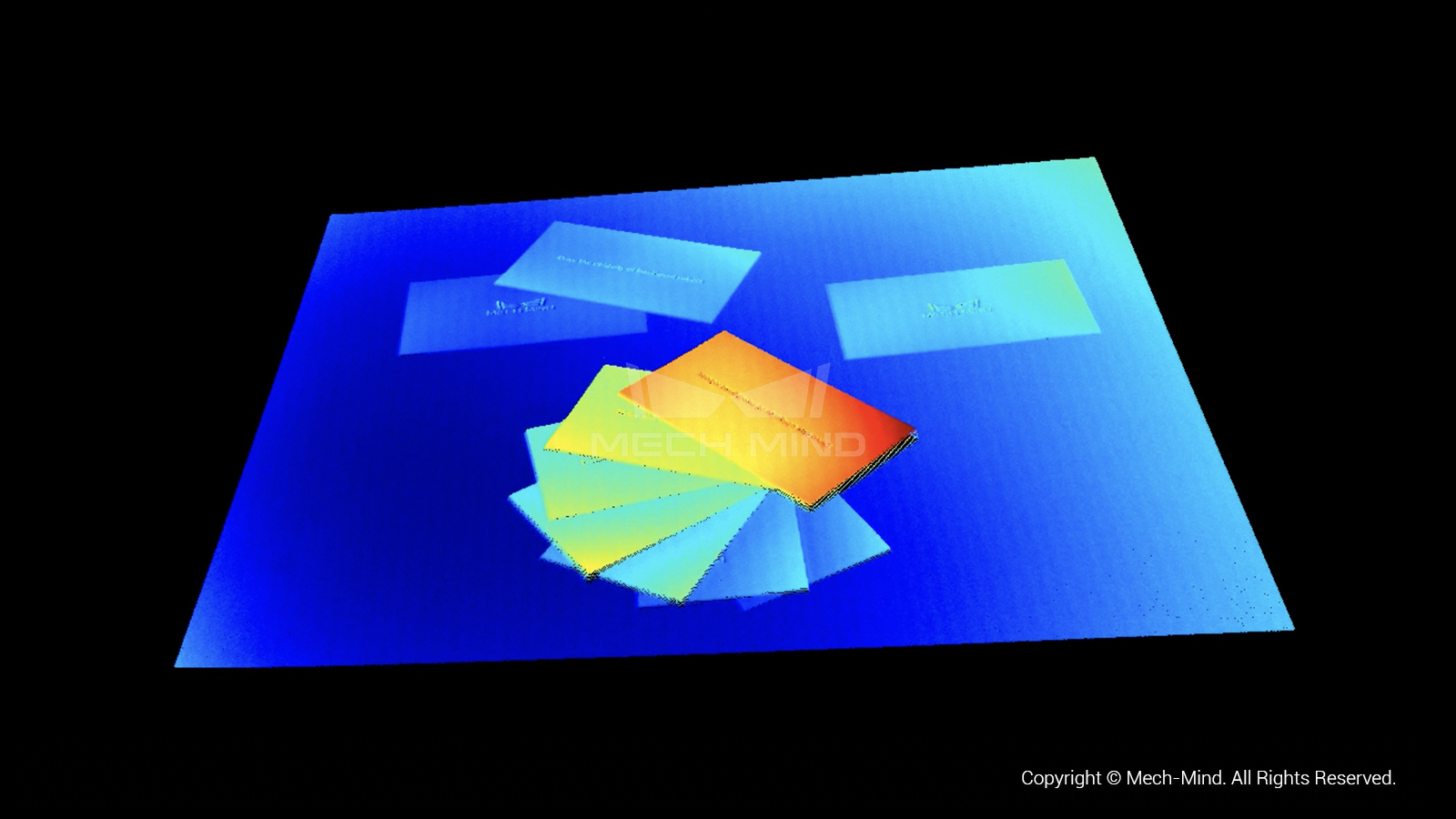

Business Cards

Mech-Eye PRO S @ 0.7 m, color rendered by height

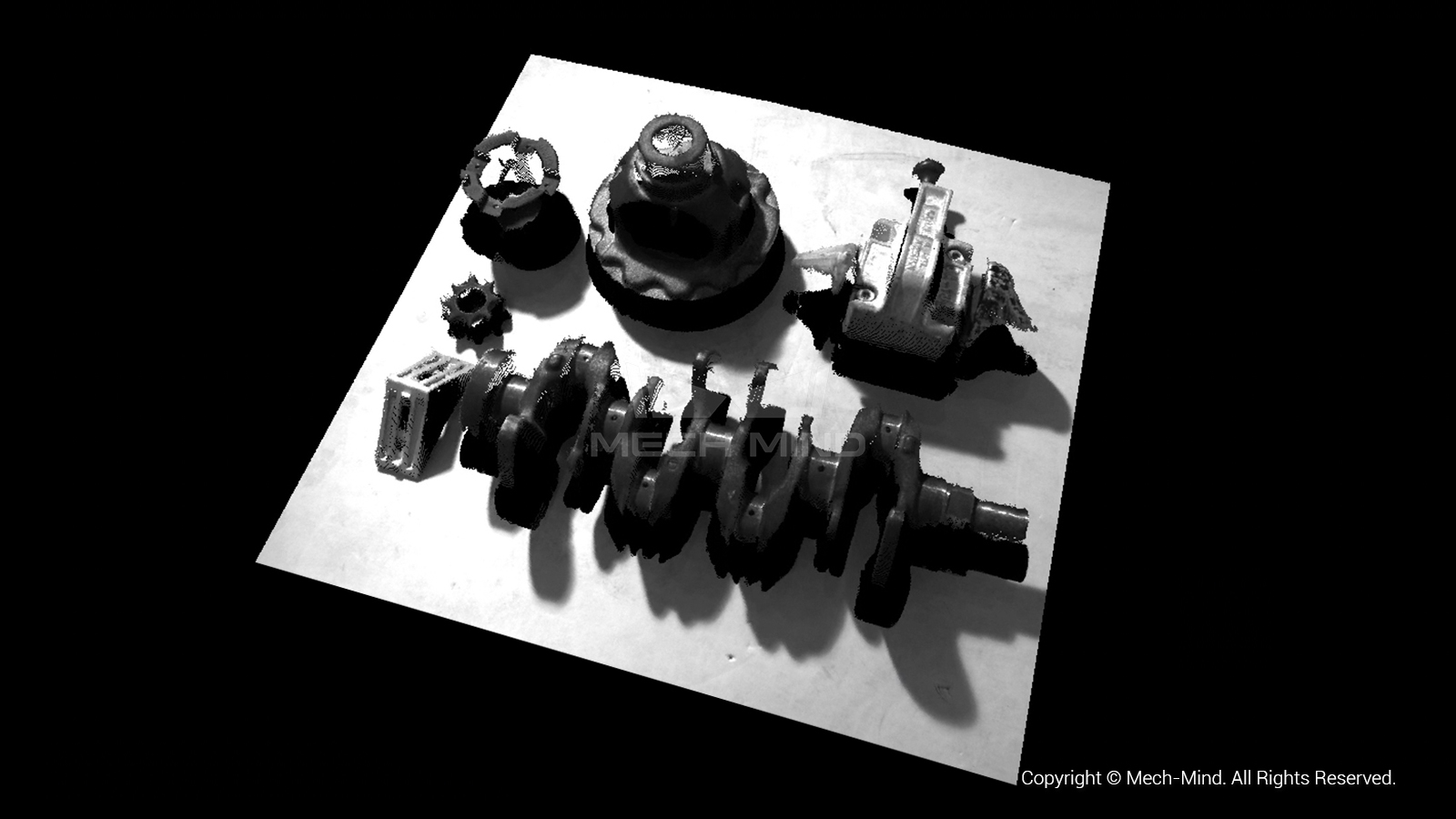

Metal Parts

Mech-Eye PRO M @ 2 m

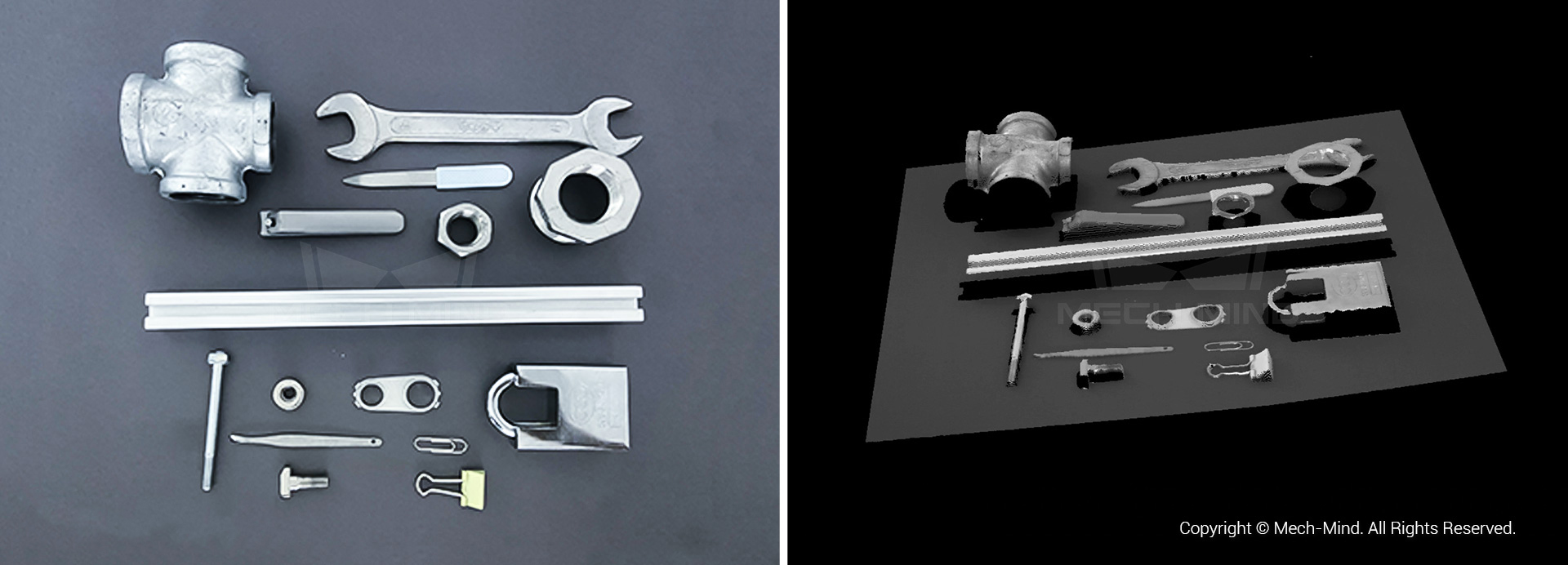

Dark Objects

Mech-Eye PRO S @ 0.8 m

Point clouds captured by monochrome version under light conditions of > 20,000 lx.

02

40% Faster Scanning Speed Combined with High Accuracy to Deliver Unmatched Performance

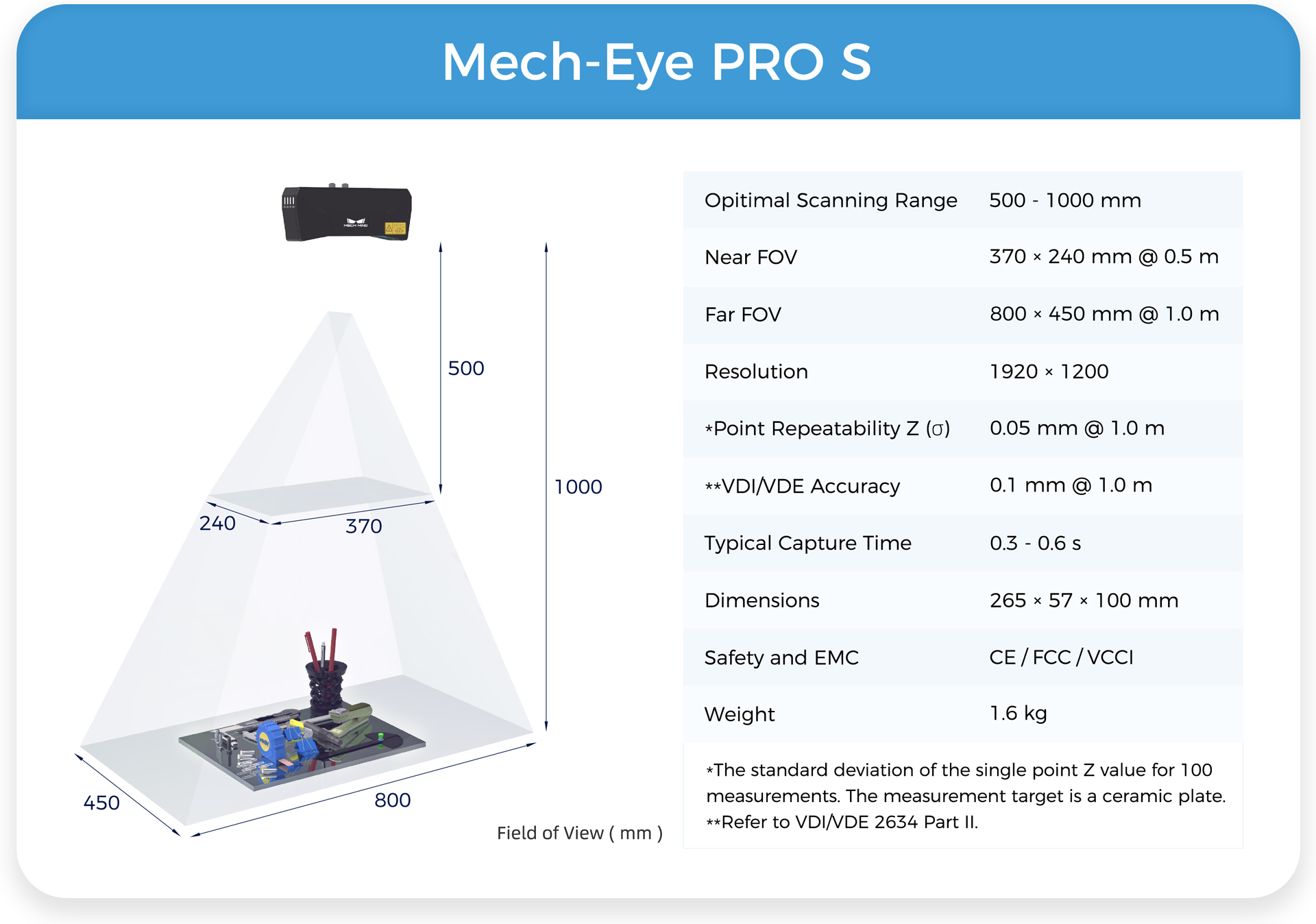

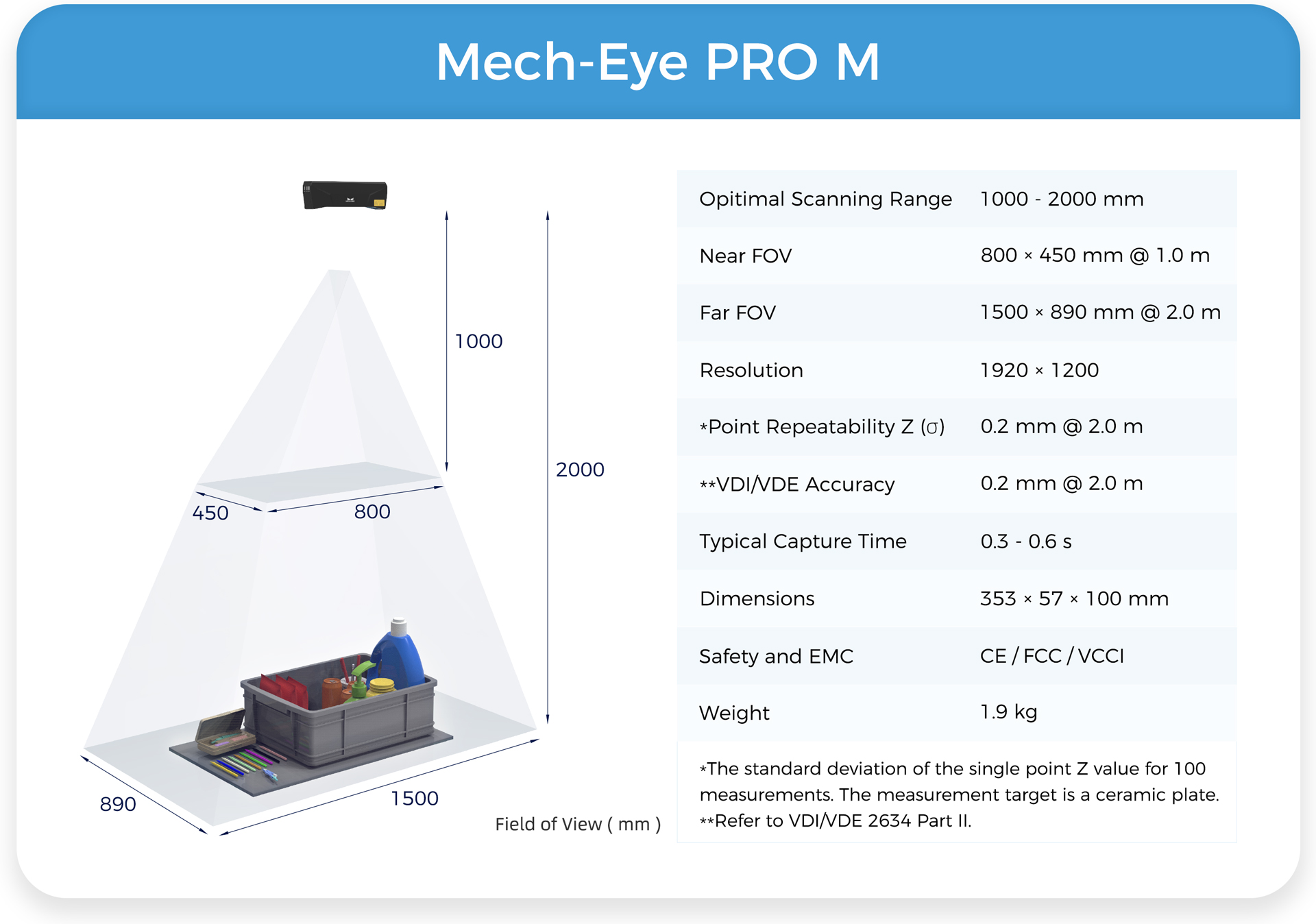

Thanks to Mech-Mind's innovative high-speed structured light technology, the image acquisition time of Mech-Eye PRO can be as low as 0.3s (acquisition time depends on specific materials and actual environment).

The incredibly high accuracy* combined with fast scanning speed enables Mech-Eye PRO to execute a wide range of demanding tasks, providing an improved cycle time without compromising the performance.

(*Refer to VDI/VDE 2634 Part II. Mech-Eye PRO S: 0.1 mm @ 1 m, Mech-Eye PRO M: 0.2 mm @ 2 m)

03

Outstanding Performance for Reflections

Sheet metals, polished metal parts, glossy packaging, and plastic wrapped objects are often considered challenging parts for 3D imaging. The new Mech-Eye PRO can provide high-quality 3D images of a broad range of reflective objects, enabling accurate and reliable picking tasks.

Reflective Objects

Mech-Eye PRO S @ 0.6 m

Point cloud captured by monochrome version under light conditions of > 20,000 lx.

04

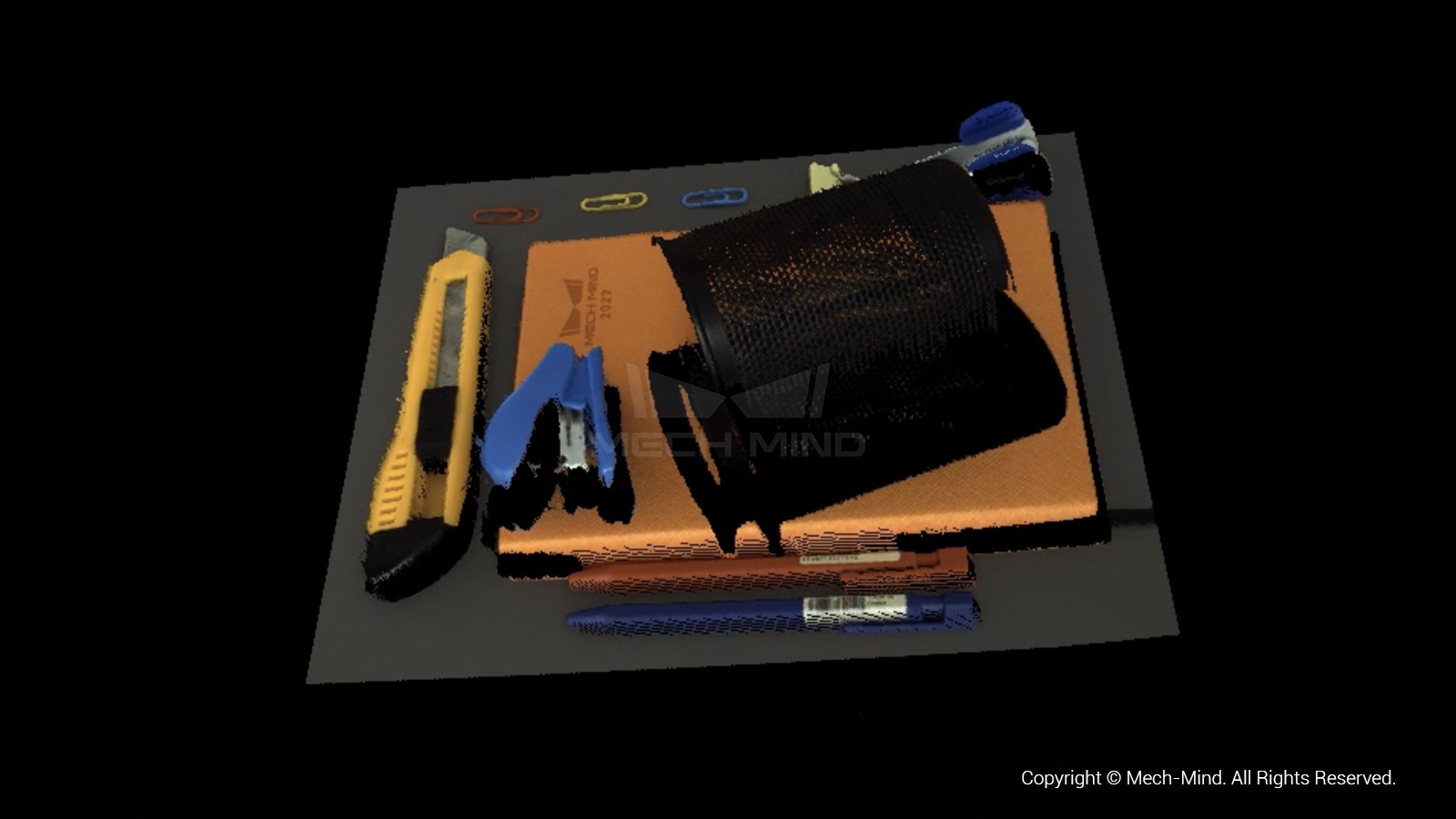

Color and Monochrome Version Options to Meet Diverse Needs

Mech-Eye PRO is available in color and monochrome versions to meet diverse practical needs. Mech-Eye PRO color camera can create accurate and high-quality colored 3D point clouds of a wide range of objects, including colored and patterned groceries, multicolored office supplies, etc.

Multicolored Goods

Mech-Eye PRO M @ 2 m

Multicolored Office Supplies

Mech-Eye PRO S @ 0.7 m

Point clouds captured under typical indoor lighting conditions.

05

Enhanced Stability with 75% Lower Temperature Drift

Thanks to a reduced temperature drift by 75%, the new Mech-Eye PRO can perform stably and reliably under fluctuating temperatures often found in real-world industrial environments.

06

40% More Compact, Easy to Install, Upgraded Interface

With a 40% more compact design, the new Mech-Eye PRO can be used even more flexibly than previous models. The reduced size & weight allows additional mounting options for Mech-Eye PRO, enabling excellent performance even in a compact space.

In addition, Mech-Eye PRO offers multi-language and -platform SDKs, a universal interface, which supports GenlCam and is compatible with Halcon and other machine vision software.

By combining Mech-Eye PRO with Mech-Vision, the graphical machine vision software and Mech-Viz, the intelligent robot programming environment, users can easily and fast implement various robotic applications.

07

Industrial Grade to Master Real-World Challenges

Mech-Eye PRO industrial 3D cameras offer a fully-enclosed aluminum alloy housing, combining light weight with high ruggedness.

They provide IP65 rating water and dust protection and are CE, FCC, VCCI, and RoHS certified. So even in harsh environments with dust, vibration, humidity, electromagnetic interference, and high temperature, Mech-Eye PRO will perform challenging tasks with great consistency and exceptional performance.

┃ Specifications

┃ Use Case

Vision-Guided Bin Picking and Machine Tending of CV Joints

Initial Situation:

While the working environment is extremely harsh for employees and manual execution is expensive and not efficient, a large auto parts factory wanted to automate the process of bin picking and machine tending of CV joints. As the parts have a finished surface and are additionally covered with anti-rust oil, these extremely reflective CV joints presented a big challenge for accurate imaging.

The Mech-Mind Solution

1. Mech-Eye PRO M high-accuracy industrial 3D camera can generate high-quality point cloud data of CV joints, even with highly reflective surfaces and complex structures;

2. Mech-Mind's vision solution supports different kinds of CV joints;

3. Intelligent collision detection and path planning algorithms automatically calculate the best picking angle and position to improve stability and reliability, preventing typical problems such as colliding with other workpieces and bins, dropping parts, etc.

The fully-upgraded Mech-Eye PRO is ideal for typical medium-range robotic applications. With its new tested and proven features, Mech-Eye PRO can accomplish a broad range of challenging applications with high accuracy, improved stability, enhanced flexibility, and shortened cycle time. It allows users to master various real-world challenges reliably while improving production efficiency and throughput.